Low-Carbon Energy-Saving Technology Pathway: Overheated Steam Drying - Isoenthalpic Closed-Cycle Energy System

This research focuses on the coupled application of superheated steam drying core technology and an isenthalpic closed-loop energy system. Leveraging the high enthalpy and low oxygen characteristics of superheated steam, it achieves efficient material drying. Combined with the energy cascade recovery and zero-emission advantages of the isenthalpic closed-loop system, it realizes energy saving, cost reduction, efficiency improvement, and low-carbon emission reduction in the drying process. It is applicable to multiple industrial fields such as food, chemical, wood, and sludge treatment, and can directly guide engineering design, equipment selection, system operation, and process optimization.

I. Core Technical Principles

(I) Core Principles of Superheated Steam Drying

Using superheated steam as the sole drying medium, this method abandons the air medium used in traditional hot air drying. Utilizing the high specific enthalpy and high heat transfer coefficient of superheated steam, it achieves rapid vaporization of material moisture through the dual effects of convective heat transfer and phase change heat transfer. The entire system operates in a low-oxygen/oxygen-free environment, fundamentally preventing material oxidation, browning, and carbonization, thus ensuring the product's color, composition, and physical properties. During the drying process, the steam and the vaporized moisture from the material mix and remain in the steam phase, resulting in no waste air emissions and creating conditions for energy recovery.

(II) Core Principle of the Isoenthalpic Closed-Loop Energy System

Based on isoenthalpic conversion as the core of energy regulation, the system integrates the superheated steam drying unit, gas-solid separation unit, energy recovery unit, and steam regeneration unit into a fully closed-loop system. The dried wet steam undergoes a continuous process of isoenthalpic cooling, dehumidification, reheating, and superheating within the loop, achieving cascade utilization and recycling of steam energy. The system only needs to replenish the small amount of energy and steam lost during the drying process due to material carryover, equipment heat dissipation, dehumidification, and slag removal to maintain stable operation. The energy recovery rate is ≥85%, eliminating energy waste at the system level.

(III) Core Logic of Coupling Between the Two

The isenthalpic closed-loop system provides a continuous, stable, and high-quality superheated steam medium for superheated steam drying, while simultaneously achieving efficient energy recovery and medium regeneration of the dried wet steam. This addresses the pain points of traditional superheated steam drying, such as high energy loss and low medium utilization. The process characteristics of superheated steam drying determine the energy flow and medium flow parameters of the closed-loop system, achieving a precise match between "medium circulation - energy recovery - process requirements," forming an energy-saving, environmentally friendly, and highly efficient drying energy closed loop.

II. System Overall Design and Process Flow

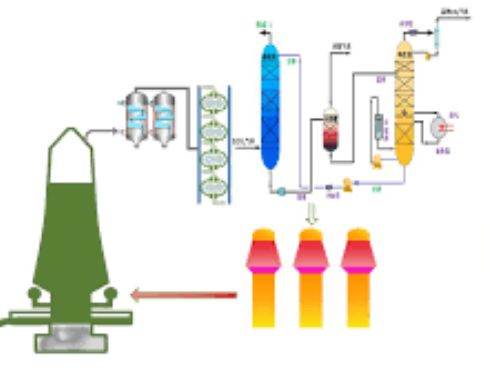

(I) System Overall Architecture

The system is designed as a fully closed loop, with no external exhaust gas/waste heat emissions. The core consists of six main units, seamlessly connected. The medium and energy flow in a closed loop within the circuit, with only loss replenishment ports and material inlets/outlets. The architecture is as follows:

Superheated Steam Generation Unit → Drying Unit → Gas-Solid Separation Unit → Isenthalpic Conversion and Energy Recovery Unit → Steam Dehumidification and Regeneration Unit → Energy and Water Replenishment Unit → Superheated Steam Generation Unit

(II) Core Process Flow

1. Steam Generation: Soft water, after preheating, enters the steam generator.

1. Saturated Steam Generation: Saturated steam is generated through heating with industrial waste heat, biomass energy, clean energy, or a small amount of fossil fuels. This steam is then heated in a heat exchanger to the required superheated steam temperature (100-350℃, 0.1-1.0MPa, superheat 20-150℃).

2. Drying Process: Superheated steam enters the dryer in a co-current/counter-current/through-flow manner, ensuring full contact with the material and rapidly vaporizing its moisture. Once the material is dried to the set moisture content, it is discharged from the outlet. The resulting wet superheated steam (superheated steam + vaporized moisture) enters the gas-solid separation unit.

3. Gas-Solid Separation: Wet superheated steam is separated by a cyclone separator and a bag filter (or ceramic filter) to remove material dust, preventing impurities from entering the circulation loop and causing scale and wear on the equipment;

4. Dust Removal: Wet superheated steam passes through a cyclone separator and bag filter (or ceramic filter) to remove material dust, preventing impurities from entering the circulation loop and causing scaling and wear on the equipment.

5. Enthalpic Conversion and Energy Recovery: The purified wet superheated steam enters an isenthalpic heat exchanger, where it undergoes cooling and dehumidification under isenthalpic conditions. The released high-grade heat energy is transferred to the soft water/saturated steam in the steam regeneration unit, achieving cascaded energy utilization. The cooled wet steam becomes saturated wet steam and enters the dehumidification unit.

6. Steam Dehumidification and Regeneration: Saturated wet steam undergoes mechanical dehumidification/condensation dehumidification/adsorption dehumidification. 6. **Replenishment of Steam and Energy:** Excess moisture is removed, restoring the steam to a dry state before it enters the superheater. The recovered heat from the isenthalpic heat exchanger, plus a small amount of supplementary energy, heats the steam to the required superheated steam parameters.

7. Replenishment of Steam and Water:Based on energy losses (heat dissipation, separation, dehumidification) and media losses (material carryover, wastewater discharge) during system operation, a small amount of heat energy (preferably utilizing industrial waste heat) is added through the replenishment port, and soft water is added through the water replenishment port to maintain stable steam flow, pressure, and temperature within the loop.

8. Circulation Operation: The regenerated superheated steam re-enters the drying unit, completing a closed-loop circulation of media and energy.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next 2025 China Agricultural Machinery Industry Sees Steady Progress and Quality Improvement

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.