Digital twins via REXS: Schaeffler digitalizes the development process in gearbox construction

Thanks to the standardized REXS data interface, repeated gearbox modeling processes are eliminated. Development times are thus significantly shortened and a basis created for the generation of digital twins that can be used to analyze operating data as part of Industry 4.0 solutions, for example.

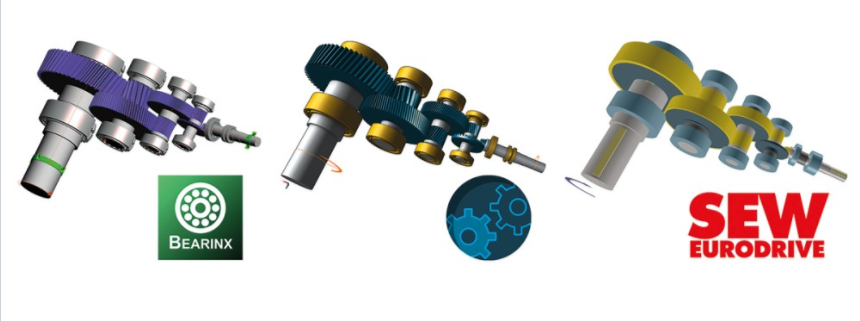

Gearbox development with REXS: Standardized and fully digitalized data transfer replaces manual data transfer

Schaeffler customers not only benefit from significantly shorter development times

The new REXS data interface provides the basis for simplified digital twin generation

A complete virtual representation of drive trains and gearboxes is only possible when gearbox, rolling bearing, and gearing specialists can digitally link their simulation models together. This makes the exchange of data across companies and systems one of the most important prerequisites for the generation of digital twins. A number of specialized software and CAE tools for designing and simulating gearboxes have established themselves on the market, each of which has its own specific points of focus. The problem, however, is that manufacturers and their suppliers still often exchange gearbox data manually, which causes time-consuming duplicate work. In collaboration with SEW-EURODRIVE and the FVA (Research Association for Power Transmission Engineering), Schaeffler has now developed an electronic data transmission system that replaces this manual exchange between CAE tools and eliminates repeated gearbox modeling processes by means of a standardized interface for gearbox data. Development times are thus significantly shortened and a basis created for the generation of digital twins that can be used to analyze operating data as part of Industry 4.0 solutions, for example.

Standardized data format in gearbox construction

The format is known as REXS (Reusable Engineering Exchange Standard), and version 1.1 offers a standardized modeling system and nomenclature for any desired gearbox with spur gear, bevel gear, and planetary gear stages as well as their components. REXS is currently integrated into the FVA Workbench from version 5.0 upwards, into all current versions of Schaeffler’s Bearinx rolling bearing analysis tool, and into SEW-EURODRIVE’s WESILAB gearbox calculation program. Even commercial CAE tool suppliers have now implemented the REXS interface or are planning its introduction as part of their next releases. A simple mouse click is all it takes to generate an REXS file from the gearbox models.

Schaeffler now offers the automatic exchange of gearbox data via the REXS interface. Customers obtain calculation results from Bearinx significantly faster, which considerably speeds up their development processes. Stephan Evert, Head of Bearing Analysis Tools Development in Schaeffler’s R&D Bearings department, spoke emphatically about the advantages: “REXS allows us to reduce the outlay for linking CAE tools and simulations in the relevant software systems while simplifying the IT architectures at the same time.” He went on to explain: “REXS can be used by the gearbox sector as a standardized data container for the generation of digital twins.”

Faster application development in gearbox construction

Gearbox manufacturers with a high proportion of customer-specific application development benefit greatly from being able to digitally exchange data with their suppliers. “The objective is to allow different systems that have their own focal points in terms of calculation to be used efficiently and effectively”, explained Dr. Heinrich Bolz, Head of Calculation and Simulation in Gear Unit Development for SEW-EURODRIVE. Regarding the open-source project, he continued: “With REXS, gearbox data can be transferred quickly and without errors, which means the interface makes an essential contribution to the optimization of our innovation process.”

The REXS interface is freeware, and is available at www.rexs.info together with all further information about current and future developments.

Visitors to Schaeffler’s trade show booth can watch a live demonstration that shows just how easy it is to exchange data models between CAE tools.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Optimum lubrication at all times: Longer machine operating times and lower maintenance costs with minimal outlay

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.